The lean methodology originates from Toyota’s manufacturing unit but it slowly became apparent thatproject managerscan use lean principles to reduce wastes and inefficiencies in any industry. From healthcare to software development, principles of lean are helping managers cut their costs and keep a competitive edge. For many American companies, being lean is the only way for them to compete on the global level against competitors from countries where the production costs are significantly lower. Lean is often referred to as ‘rigorous elimination of waste’ due to the methodology’s focus on creating the most efficient environment that fosters growth. To implementlean project managementin any team, the manager must follow the three pillars of lean. The three pillars are to spotting wastes, stimulating improvements daily, and recording those improvements.What is lean?

Implementing lean in any environment is an iterative process that helps you identify areas where no value is added to your product. To be completely free of waste, a process must go through lean multiple times.

Another thing that makes lean great is its adaptability. It has a track record of working in several different industries and inproject management, the methodology even grows with the industry. With the whole world adopting IoT and Industry 4.0, lean is becoming data-driven. It isgrowing with the industryto keep on delivering exceptional value to the customers.

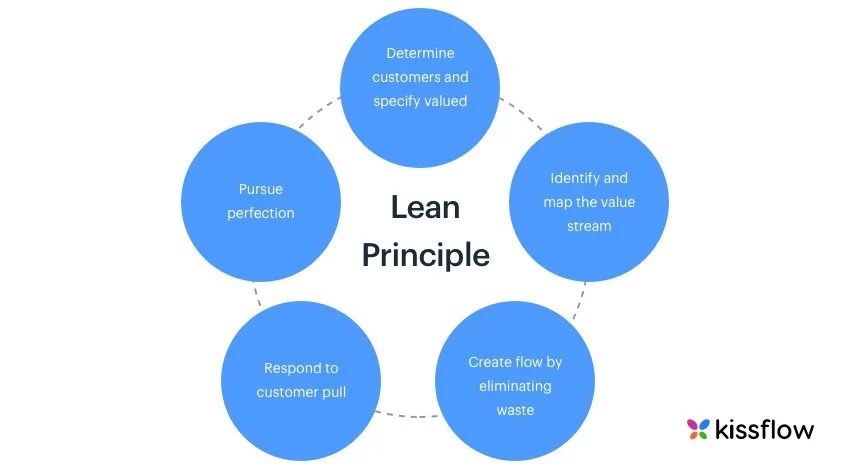

5 principles of lean explained

First described by the founders of Lean Enterprise Institute in 1997, the principles of lean act as a building block on which the entire methodology stands. In theproject management book“The Machine that Changed the World,” Womack and Jones described the five principles of lean as the ultimate recipe to improve the efficiency of a workplace.

1. Identify value

The first lean principle is all about identifying the needs and requirements of the customers. It important for managers to evaluate the actual needs of their customers by conducting detailed interviews and analysis. Identification of value is especially important in the case of novel products.

Customers usually are not articulate enough to get their complete requirements across and managers are responsible for keeping the customers engaged and understand their expectations.